SmartFrame™ Open Field System Dramatically Enhances Validation and Diagnostic Efforts!

The SmartFrame Open Field System has been designed with advanced features and ease-of-use as primary objectives. It uses MotorMonitor software common to all Kinder Scientific motor activity products with post analysis routines for greater flexibility in analyzing data. The advanced diagnostics use an exclusive Kinder Scientific 4-level test that runs automatically before each session.

Named the SmartFrame because of it’s onboard intelligent circuitry, this system dramatically enhances validation and diagnostic efforts. An excellent choice for open field work for both rats and mice because of its standard high density beam spacing. Systems are also available for larger animals – please consult us for details.

Large Animal Open Field

For studies with larger animals or when our standard size open field does not meet the paradigm requirements we offer our Large Animal Open Field unit. With the same options and advanced software tools as our standard open field, this unit offers even more flexibility for your lab.

Sound Isolation Chamber

Available in all Open Field sizes. Our Sound Isolation Chamber uses our unique sound deadening technology to create these chambers for sounds sensitive studies, offering 10dB greater attenuation than our competition.

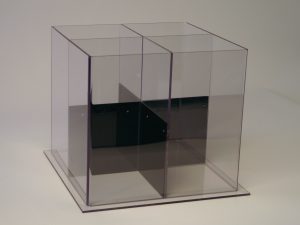

Light/Dark Insert

These infrared transparent inserts are available for Open Field Frames in varying sizes.

Key Features:

Automated Diagnostics and Built-in Validation Aids.

Most commercial systems have some type of beam check, but ours is capable of real diagnosis! Our advanced diagnostics interrogate the performance level of the photobeam components. It’s much more than a simple on/off test. These sophisticated tests provide 4-level circuit evaluation that ensures proper operation, automatically, before the start of each session. The system will tell you when a photobeam is going to fail before it actually happens! In the unlikely case a photo beam failure does occur, you may choose to either correct the failure or remove the failed enclosure before continuing. The session will begin only after a successful automatic diagnostic has been completed.

Shown above is the 4-level test status screen. The serial numbers above the green indicator blocks and in the title block are electronic serial numbers for system components. With these reference numbers, the factory can track the life history of each component. Observe the enclosures labeled Off Line. The system automatically knows what is connected and what is not! The Automatic Diagnostic feature isolates faulty components during trouble shooting.

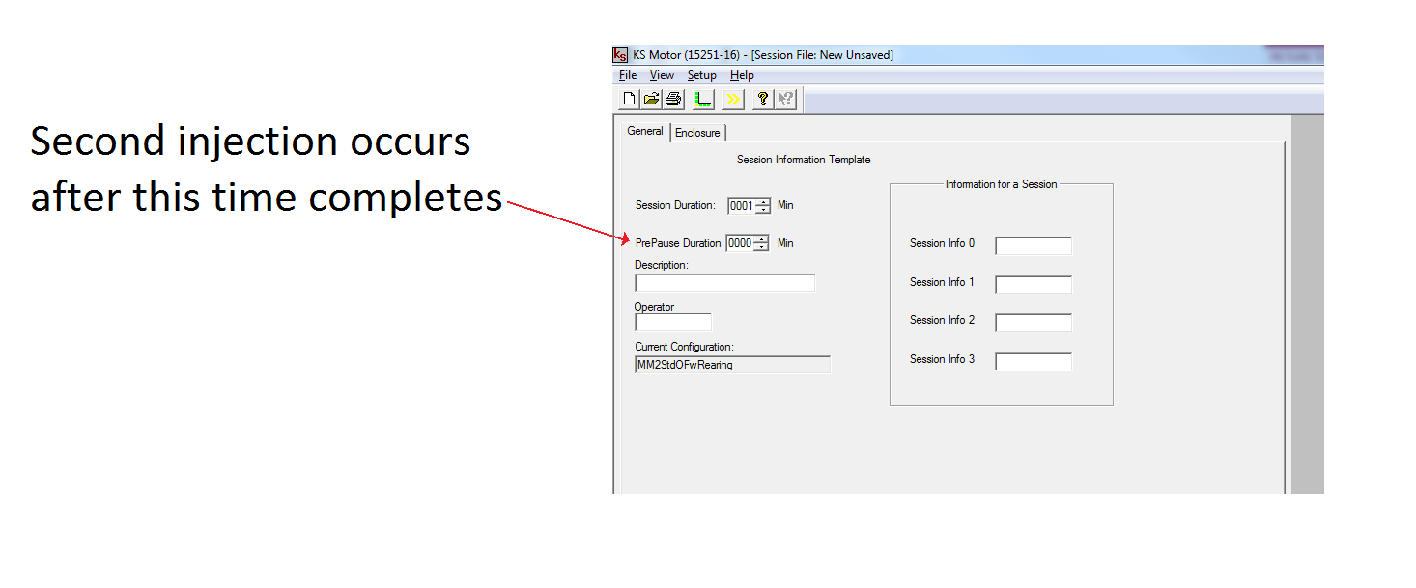

Built-in Pause option.

The Built-in Pause option feature makes it possible to have a dual injection phase where the system keeps track of and notifies the technician when it is time to make the second injection and does not collect irrelevant data during the second injection effort. This keeps you from having to rush to inject an animal and also provides you with only relevant data. As a result, in studies with a large number of animals being studied simultaneously, this is extremely useful!

User-Defined Zones and Post-Run Tracking.

User-Defined Zones and Post-Run Tracking.

The MotorMonitor software allows you to define your own zones! In addition, you can see the animal’s path post-run.

Post Analysis Approach.

All MotorMonitor products collect the essential beam activity during runtime without calculating any of the measures. Because of this approach the scientist can change any of the analysis parameters such as time bin size, number of zones, and zone layout and re-analyze existing data for a new presentation of that data. A simple example would be that you can have a single time bin for the entire session for summary data and/or multiple time bins (in second resolution) so study how particular measures change over time.

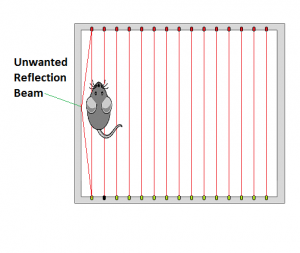

Solving the “you can’t see me problem!”

Because of the nature of infra-red photobeam characteristics, beams that are close to polished surfaces (which is what all enclosures are) can gave a dead zone close to the middle of the arena. This dead zone causes the subject to disappear from the system view. Our proprietary filtering design eliminates this common problem to provide more accurate data.

On the receiver side of the enclosure the sensors that appear green are receiving the emitted infrared emission from the opposite side. As shown here the first beam appears green but should appear black (blocked) but is not because the beam is bouncing off the polished wall of the enclosure.

On the receiver side of the enclosure the sensors that appear green are receiving the emitted infrared emission from the opposite side. As shown here the first beam appears green but should appear black (blocked) but is not because the beam is bouncing off the polished wall of the enclosure.

General Features:

32 Infrared PhotoBeams (16X & 16Y)

Individual start button at each station

Automatic 4 level diagnostics

Maximum Stations 30

User Definable Zones – not factory installed!

Post Processing Analysis

Session Templates

Individual Runtime Clocks for each station

User selectable output measures

Optional Advanced Graphic Comparators – HotSpots, Playback and OverTime

Measures:

Movement Metrics

X Ambulations

Y Ambulations

Fine Movements

Lever Presses

Rearing Events

Rearing Time

Custom Events

Basic Movements (Total X/Y Breaks)

Hole Pokes

Zone Metrics

Time in Zone

Time at Rest

Entries into Zone

Time Active

Pokes into Zone

Distance

Computer Requirements: PC with Windows 7 Pro or Windows 10 Pro

Power: 90-240vac 50-60 Hz

Open Field:

Overall dimensions: 22.1″ wide x 22.1″ long x 15.83″ high

Subject Field dimensions: 16″ wide x 16″ long x 15″ high

Large Animal Open Field:

Overall dimensions: 39.0″ wide x 38.77″ long x 15.83″ high

Subject Field dimensions: 32″ wide x 32″ long x 15″ high

Maximum number of stations: 32

PhotoBeams: Infrared PhotoBeams with 16 X and 16 Y resolution

Housing: Brushed stainless steel

Computer Interface: A single ethernet connection or RS232 serial port, regardless of the size of the system!